- Core competencies

- Products

- Contact & Consulting

- Company

Combined sewage overflow screens

The contamination of surface water resources by combined water from overflow systems and partly also from stromwater tanks, consists of all the solids which are present in the waste water. This involves a very wide range of dissolved, semi-dissolved, fiber and solid substances with different structures and specific weights (plastic strips, sanitary towels, diapers, condoms, faecal matter, paper etc.).

The increasing restoration of surface water resources to their natural state makes it essential to avoid such discharges of floating material in the future. The construction of immersed walls in overflow structures only enables part of the discharge of floating substances to be avoided, because considerable flow velocities are likely to build up with the generally short spaces which exist between the immersion walls; these velocities tend to increase the discharge of solid material.

Continuous basins can only perform their function to a limited degree because of the large volumes of water and the increasingly high proportion of light materials. Retention basins and retention channels have the drawback that untreated combined water is discharged into the outfall once they are full.

A basin-screen combination is the best way of meeting the criteria in such cases. In this concept, retention of the heavily contaminated flushing surge is the main task of the basins. On the other hand, the screen removes light, floating and solid substances which would otherwise contaminate the outfall area (Figures 1 and 2).

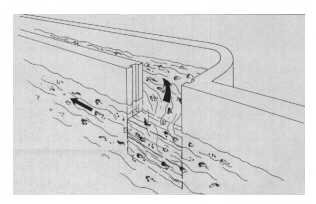

Figure 1 Outfall area contaminated by

combined sewerage overflow

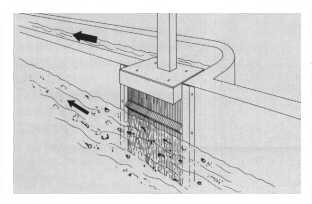

Figure 2 The same stream section after construction of a stormwater retention tank with ROMAG high performance screens

ROMAG CSO-Screens

ROMAG specializes in the development and manufacture of screens for overflow structures. For many years they have been collaborating with professional experts from the water resources sector and have therefore acquired extensive experience and references both at home and abroad.

The ROMAG CSO-screen has the following typical features:- high operational reliability

- automatic mechanical cleaning

- corrosion-resistant design

- robust construction

- low-maintenance requirement

- narrow bar spaces (4mm)

- controlled handling of the screened material

The screened material is transported to a predefined location during the storm event.

This:- prevents any build-up of solids in the inflow zone

- ensures that the screen stays clean even after the event and needs no manuel cleaning.

Design features

ROMAG CSO-screens are designed to a modular system. All types consist largely of elements which can be put together to obtain the most suitable type of screen for each particular application. The robust frame structure holds the screen grate, the cleaning carriage with the comb stacks and the hydraulic or pneumatic cylinder.

The screen grate is built up from pre-tensioned narrow screen bars. The small bar cross-section ensures optimum use of the screen area, low screen resistance and high flow capacity. The standardized bar interval is 4mm, so that all the undesirable floating materials are retained.

One or more cleaning carriages are arranged on the outflow side depending on the screen length. They travel in guides over the screen surface. The comb stack which is mounted on the cleaning carriage engages in the screen grate, supports and guides the screen grate bars. The comb stack accordingly replaces the transverse stiffener elements which are undesirable in water cleaning systems. The screen cleaning is switched on and off as a function of the level. Drive is normally hydraulic .

Figure 3: ROMAG high performance screen, Type RSU viewing from the inflow side

The ROMAG CSO-screen is made in 4 different types.

Type RSW ROMAG screen with horizontal throughflow

- low-cost solution

- simple structure

- easy access to screen

- low head loss

Type RSU ROMAG screen with up through unit flow

- Suitable for installations with low space in height

- Outflow and emergency overflow possible on both sides

- Ambitious regarding water flows and maintenance

Type RSW-K ROMAG screen typ RSW combined with a controlled overfall weir on the discharge side

- optimal usage of the existing storage volume

- substantial reduction of number and quantity of the discharges

- best possible protection of your receiving waters

Dimensions and performance

The ROMAG CSO-screen can be adapted to the structure in which it is installed and also to the required flow capacity.

- Length: 3,0 - 9,0 m

- Width or height: 0,4 - 1,2 m

- Capacity: 200 - 5000 l/s

- Connected load: 400 V, 1,5 - 3 kW

Figure 4: High performance screen type RSW in an overflow structure, viewing from the outflow side

Operational dependability and maintenance

The ROMAG CSO-screen is typified by its robust structure. When screened material becomes clogged, the fault is cleared by repeating the operation. A special changeover valve on the drive unit controls the movement of the cleaning carriage. No fault-prone limit switches are needed. The hydraulic drive unit can be installed outside the screen area. Only two hydraulic lines lead into the wet chamber. Continuous cleaning occurs during operation. No cross-bracing is required in the screen area. The screened material is diverted and scraped off at the end positions. Controlled transport of screened material can be effected to a predefined location. Emergency overflow is provided.

The ROMAG CSO-screen requires very low maintenance. After the storm, the screen is so clean that subsequent manual cleaning is superfluous. A monthly functional check or verification after exceptional rainfall will be sufficient.

The entire design complies with the SGK corrosion protection directive (C6d/1995) and the CE standards.Possible uses:

Screen in storm water retention tank

- rainwater settling basin

- rainwater basin

Screen in overflow structure

- barrage channel

Screen in overflow structure

- in front a storm water tank

ROMAG's Baby

ROMAG's CSO- screens normally operate horizontally and require an installation length of at least 3 m. They are thus unsuitable for many, less recent structures with small or narrow spillway openings.

The new RSS CSO-screen with raised screen has been designed for opening widths of 40 - 120 cm resp. for structures characterised by cramped conditions. Apart from operating vertically, everything else functions in precisely the same way as on the well known ROMAG CSO-screens which have been used very successfully for many years now and which enjoy an excellent reputation on the market. The RSS is designed for flow rates of 80 - 300 l/s.

England and Ireland with their many small storm water relief tanks and basins are particularly interested in the RSS. During the course of a series of tests covering several months, a water and sewage authority in Britain's north-east determined that the RSS retains 95 % of the solids and suspended matter > 6 mm in the relief water. The first RSS has already been sold to Spain.Interested? Our offer will be made to mesure.

- Products