- Core competencies

- Products

- Contact & Consulting

- Company

RSW

of the ROMAG high-performance CSO screen RSW:

- Dispenses with the need to make high investments in retaining capacity volume

- Prevents unnecessary contamination of the receiving water courses

- Is safe and reliable to operate

- Permanently performs mechanical cleaning action

- Is resistant to corrosion

- Is rugged

- Requires little maintenance

- Has a small bar spacing (4 mm)

- Transports the caught material from the inlet zone

- Materials either 316L or 304L

RSW 5X3/4

Such pictures are a thing of the past thanks to the use of the ROMAG high-performance CSO screen RSW.

The CSO screen RSW, fitted vertically between the discharge culvert and the relief sewer, reliably retains all visible solids when the excess water flows through.

Water flows horizontally through the screen. It is mounted on the owner‘s prepared concrete sill. The height of the sill depends on the hydraulic survey and is lower than the required water level when relief operations start. The retaining panel attached to the rear side of the screen is designed to achieve a uniform screening rate but so that a CS of max. 1.50 m/s is not exceeded. The upper edge of the screen is designed as an emergency spillway. The water is discharged via the screen if the cleaning system fails (e.g. in the event of electrical power failure) or if overloaded.

Particular importance has been attached to operating safety and reliability. The first step towards this relates to omission of components susceptible to failure such as limit switches. In addition, the electrical and hydraulic control elements are arranged outside the critical zone so that only two hydraulic pipes lead into the wet chamber. The clever design means that the CSO screen cleans itself constantly. There is no cross-bracing which could to lead to build-up of caught material in the screen area at the inlet end. In the event of solid material causing brief clogging, the control system is designed to repeat the comb movement at this point until the screen is unobstructed again.

CSO screen RSW, inlet end (2 modules high)

CSO screen RSW, relief end (without retaining panel)

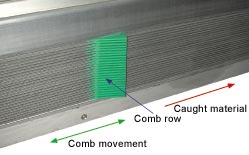

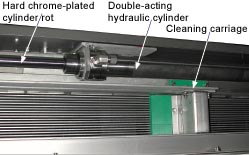

The ROMAG CSO screen RSW consists of a rugged frame made of stainless steel sections. The horizontal screen bars are braced in this frame. The cleaning carriage which is moved to and fro by a double-acting hydraulic cylinder is located on the rear side. Several comb rows of asymmetrical triangular shape move through between the screen bars. The water flowing through forces the caught material against the bars where it is moved on by the cleaning combs with their „steep end“ in longitudinal direction. The flow direction assists this movement. During return travel, the „flat end“ of the combs slides through beneath the caught material. The traverse paths and shapes of the combs are intermatched so that each cleaning comb transfers the caught material to the next cleaning comb. It is slid to the end of the screen and is then discharged with the outflowing effluent to the sewage treatment plant. This prevents a problematic concentration of caught material at the inlet end.

The CSO screen RSW has proven successful in several hundred applications. However, close

cooperation with the offices and agencies involved is necessary in order to achieve a reliably operating installation. This is necessary in order to determine and comply with the hydraulic boundary conditions.

This concerns a streamlined feed to the CSO screen and the discharge to the sewage treatment plant with the required downgrade:

The caught material which is transported by the screen to a defined point must move continuously downwards into the discharge path. For instance, a shaft for the caught material may need to be used depending on local conditions.

Inlet channel of the AIRE sewage treatment plant in Geneva, 3 RSW10 X 8/4,

Qmax. total = 18,000 l/s View from relief sewerPreselection table

Nominal length NL in m

2

3

4

5

6

7

8

Tot.length in m

2.84

3.84

4.84

5.84

6.84

7.84

8.84

Masonry

opening in m3.00

4.00

5.00

6.00

7.00

8.00

9.00

Module

Height H

Average max.

CSO screen capacity in m3/smm

2

330

0.30

0.41

0.53

0.67

0.82

0.96

1.10

3

426

0.44

0.62

0.79

1.01

1.22

1.44

1.66

4

522

0.59

0.82

1.06

1.34

1.63

1.92

2.21

5

618

0.74

1.03

1.32

1.68

2.04

2.40

2.76

6

714

0.89

1.24

1.59

2.02

2.45

2.88

3.31

7

818

1.03

1.44

1.85

2.35

2.86

3.36

3.77

8

914

1.18

1.65

2.11

2.69

3.27

3.84

4.31

9

1010

1.33

1.85

2.38

3.03

3.67

4.20

4.85

10

1106

1.48

2.06

2.64

3.36

4.08

4.67

5.39

11a

1202

1.62

2.27

2.91

3.70

11b 1252 4.49 5.13 5.92 12a

1298

1.77

2.47

3.17

4.03

12b 1348 4.90 5.60 6.30 13a

1394

1.92

2.68

3.44

4.37

13b 1444 5.13 6.07 6.82 14a 1490 2.07 2.88 3.70 4.71 14b

1540

5.52

6.53

7.35

a = Height H for NL 2 to 5

b = Height H for NL 6 to 8Dimensions

Interested? Our offer will be made to mesure.

- Products